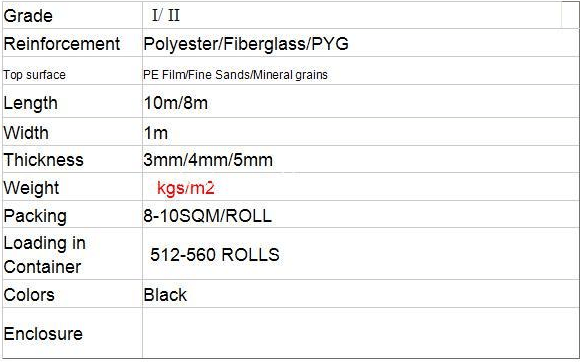

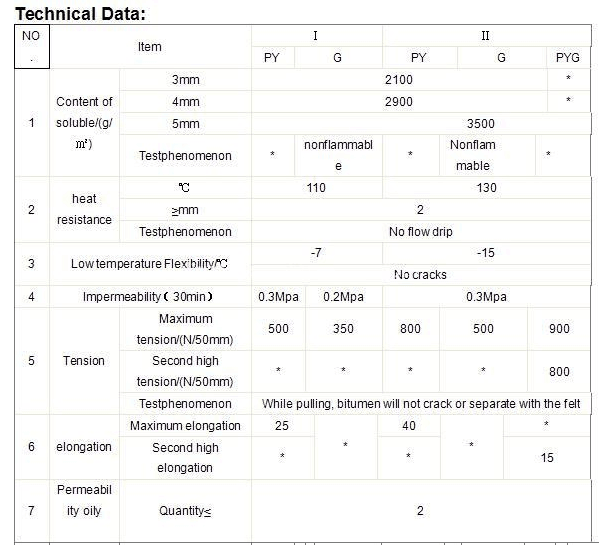

Glass fiber based APP modified bitumen waterproofing membrane

Description:

Glass fiber based APP modified bitumen membranes are made by soaking the base thermoplastics (such as a tactic polypropylene-APP,APAO.APAL) modified bitumen, then covering double faces with elastomeric (SBS)or thermoplastics (APP,APAO,APAL)modified bitumen, and last finishing the upward face with fine sands, mineral slates or polythene membrane etc. While downward face with fine sands or polythene membrane, It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature; easy application, no pollution, and long service life, etc .APP modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions, while APP specially suitable to high temperature and strong sun-shining.

It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature; no pollution, and long service life, etc. SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions, while APP specially suitable to high temperature and of strong sun-shining.

Application:

Make sure the roof deck smooth, and dry (moisture<9%), then apply the surface oroof deck homogeneously with a kind bitumen paint, till dry to start application.

There are two methods in application:

One way is by heating and melting method. Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing), then install the membrane filly bonded to the roof deck with overlaps of 5-250px.b. The other way is by cold adhesive method. Pour the cold adhesive homogeneously on the roof deck, then roll the membrane to install it to be fully slicked to roof deck. By heating and melting method and by cold adhesive can be used in alternation in application as requested.

after application, a full serious inspection is required to sure no air bubble, no falling away, etc. to guarantee the waterproof life.

Storage:

Storage and transportation, the different types and specifications of the products should be stacked separately and

should not be mixed. The storage temperature should not be higher than 50 ° C, stand up storage height of not

more than two layers;

Storage and transport of different types and specifications of products should be stacked separately and should not

be mixed. The storage temperature should not be higher than 50 ° C, stand up storage height of not more than

two layers;

normal storage conditions of transport, storage from the period from the date of production for one year.

Company Information

Weifang Choice-Link Trading Company is the import and export department of our waterproof materials manufacturer. We have 4 waterproof materials factories since 1997 in China. The company produces SBS/APP modified bitumen waterproofing membranes, Self adhesive bitumen waterproofing membranes, Self adhesive bitumen flashing tape, Self adhesive butyl waterproofing tape, PVC/TPO/HDPE/EVA waterproofing membranes, Polymer compound waterproofing membrane, Liquid bitumen coating, etc, our company also export Non woven polyester mat for bitumen membranes, Glassfiber mesh compound mat for bitumen membranes, Glassfiber mesh, Modified bitumen membrane production lines, etc

Our products are sold in over 20 countries all over the world. Approximately 70% of the total produced materials are supplied to the China market while the remaining 30% are exported to European countries, Middle East, South East Asia, South American and U.S.A.

Honest is our business policy, quality and service first. The key of the successful activity in the high quality of research and controls before, during and after production.